WEGO + DynoJet + SuperFlow Tech Info

WEGO™ AFR Wide-Band Systems - Dyno Tech Notes & Tips

Operating An Engine Dynamometer and Using A WEGO™ System?

Here's Some Helpful Info & Tips To Help You Get The Most Out Of Your WEGO™!

Quick Links

Click A Subject Below To 'JUMP-DOWN' To The Tech Note Section

Power Supply Units Compatible With WEGO™ Dyno Systems

WEGO™ Dyno Power Supply Options Single and Dual Channel Systems

XP POWER® Model #AEL80US12 - AC/DC Power Supply

TDK-Lambda® Model #DT80PW120C - AC/DC Power Supply

WEGO™ Dyno Power Supply Option - WEGO™ IIID Eight-Channel System

For Eight-Channel dyno installations using Daytona Sensors™ #111003 Four WEGO™ IIID Eight Pack Systems, dyno operators can use the Tenma® Model #72-7670 25 amp power supply available from MCM Electronics® online at www.mcmelectronics.com.

Tenma® Model #72-7670 25 amp power supply

WEGO IIID™ Eight-Channel System

t can also be used to float charge a 12 volt battery.

Interfacing A Dynojet® Dynamometer To A WEGO™ System

Interfacing A Superflow® Dynamometer To A WEGO™ System

Using Excel Spreadsheets With A Dynojet® Power Commander® System

NOTE: While we cannot provide tech support for Excel® related software performance issues or help you with individual tuning files, we do however kindly appreciate all comments, suggestions, and feedback about our new approach to data transfer. If you have any feedback regarding this topic, please create a ticket at support.jmschip.com with your opinion and details.

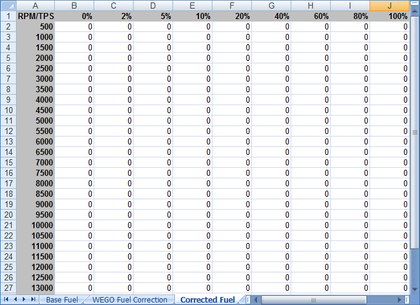

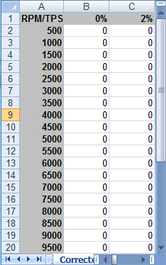

The current product version of WEGO™ software supports all ‘Copy and Paste’ operations. Some of our early versions do not have this functionality. Spreadsheets for use with the WEGO™ system and PC have default filenames containing “WEGO_PC.” The first type (with “AFR” in the filename) has corrections based on WEGO™ AFR data. The second type (with “Fuel” in the filename) is based on WEGO™ fuel percent corrections. Standard spreadsheet table rows are in 500 RPM increments. For PC tuning files that utilize table rows with 250 RPM increments, use the ‘Advanced’ spreadsheets and read the additional notes below. Use the following guidelines to choose between “AFR” or “Fuel” versions:

User Guidelines - PC Corrections Based on WEGO™ AFR Data

- The FIRST sheet is Base Fuel values. Copy the fuel table values from the PC to the Base Fuel sheet.

- The SECOND sheet is WEGO™ AFR Data. Copy the AFR Data from the WEGO™ software to the WEGO™ AFR Data sheet.

- The THIRD sheet is Target AFR. Edit the values in this sheet to your desired target AFR values.

- The LAST sheet is Corrected Fuel. These are the calculated fuel values required to achieve the target AFR values.

- Copy the corrected fuel values back into the PC. The cells in this last sheet have calculation formulas. Be careful not to type anything into these cells as this will corrupt the formulas.

User Guidelines - PC Corrections Based on WEGO™ Fuel Percent Correction Data

- The FIRST sheet is Base Fuel values. Copy the fuel table values from the PC to the Base Fuel sheet.

- The SECOND sheet is WEGO™ Fuel Correction. Copy the fuel percent correction data for the 60% to 100% TPS columns from WEGO software to the WEGO™ Fuel Correction sheet. Leave the 0% to 40% columns blank.

- The LAST sheet is Corrected Fuel. These are the calculated fuel values required to achieve the target AFR value.

- Only the values in the 60% to 100% TPS columns will change. Copy the corrected fuel values back into the PC. The cells in this last sheet have calculation formulas. Be careful not to type anything into these cells as this will corrupt the formulas.

Dynojet® Power Commander® - Converting Software Table Rows From 500 RPM Increments To 250 RPM Increments

Grounding Wide-Band Exhaust Oxygen Sensors On A Chassis Dynamometer

Vehicles operated on a chassis dyno will generate considerable electrostatic charge. The Bosch® LSU 4.2 wide-band exhaust gas oxygen sensor used with the WEGO™ requires a ground connection to the sensor body in order to dissipate electrostatic charge. If the sensor body is not grounded, electrostatic charge will build up until a discharge to the sensor element occurs. This may damage the sensor and input circuitry on the WEGO™ unit.

We recommend grounding the vehicle to the dyno frame while in operation. You can use a length of 16 AWG wire with one end secured to the dyno frame and the other end equipped with a heavy duty alligator clip that is attached to the vehicle frame or other vehicle ground point. The dyno frame or chassis must be connected to building electrical ground in accordance with National Electrical Code (NEC) requirements. Improper grounding will cause serious problems.

If grounding the vehicle is not convenient, you can use Daytona Sensors Part #115011 grounded sensor, Part #115012 six wire extension cable with ground connection, and Part #115013 ground wire kit for installation at the WEGO™ (see below). Please refer to the Grounded Sensor Tech Note at the right for full details.

Part #115025 Grounded Wide-Band Exhaust Gas Oxygen Sensor For WEGO™ Chassis Dyno System Kits

Part #115028 Ground Wire Kit For All WEGO™ Chassis Dyno Systems

Grounded Extension Cables For All WEGO™ Chassis Dyno Systems

Part #115026

Part #115027

Part #115024

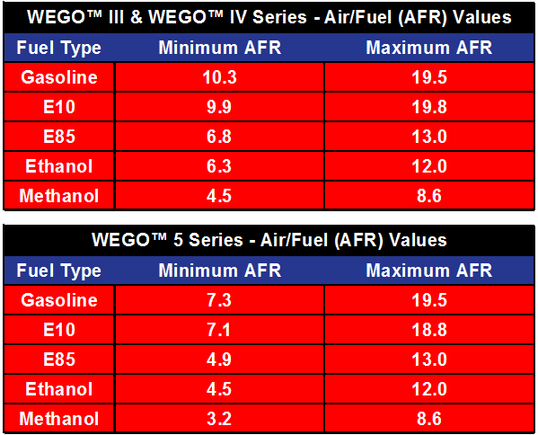

WEGO™ Systems Fuel Compatibility

All WEGO™ Systems - Scaling For Interface To Data Acquisition or Dynamometer

WEGO™ '8-Pack' System - V8 Race Engine Individual Cylinder AFR Monitoring

Daytona Sensors™ Dual Channel WEGO™ IIID units are intended for connection to an existing data acquisition system for dyno test lab or professional racing use. These units do not include an LED display or any internal data logging capability. They have 0-5V analog AFR outputs. The analog outputs are linearly scaled with 0V=10.0 AFR and 5V=20.0 AFR (the useful range is 10.3 to 19.5 AFR) and are compatible with industry standard 0-5V analog inputs on most data acquisition systems.